What is a Boring Head?

A boring head is a tool used to make a ‘proper hole’. Generally, one would use an HSS (High-Speed Steel) or solid carbide drill to remove the material or to make a hole. Those drills are available in most standard sizes, which is indeed helpful. The issue is you may not get drills of all sizes, especially where you have a male-female component fitting type requirement or a die-molding job. For example, it would not be easy to procure or make a drill size of 15.65 mm. Alternatively, you may look for any drill size lesser than or equal to 15 mm and do the rest using a Micro Boring Head. So, a micro boring head is a tool used to remove material uniformly through an inner diameter (or outer diameter) to achieve a given size with acceptable tolerance, ovality, and surface finish.

C-type Dia 50 mm Micro Boring Head from Boro-Tech

Dia 62 mm Micro Boring Head with BT40 Adaptor from Boro-Tech

Finish Boring Head with CCMT09 Cartridge from Boro-Tech

Uses of a Boring Head

A Micro Boring Head is used to make bores from as small as 4 mm to as large as 250 mm. However, some brands, such as Sandvik (check CoroBore® 824 XS) have special tools that can make bores from as low as 1 mm to as large as 2700 mm such as D’Andrea. A boring head will be required where you need a better bore in terms of ovality, tolerance, and surface finish.

An ovality will be where you will get a different measurement at different diametrical points along the circumference. This means, that from the top view, the hole is not circular but rather oval. This is because of the asymmetrical removal of material from the hole. You may use a HSS reamer to get the ovality in control but as with drills, procuring a reamer for every size becomes all the more expensive.

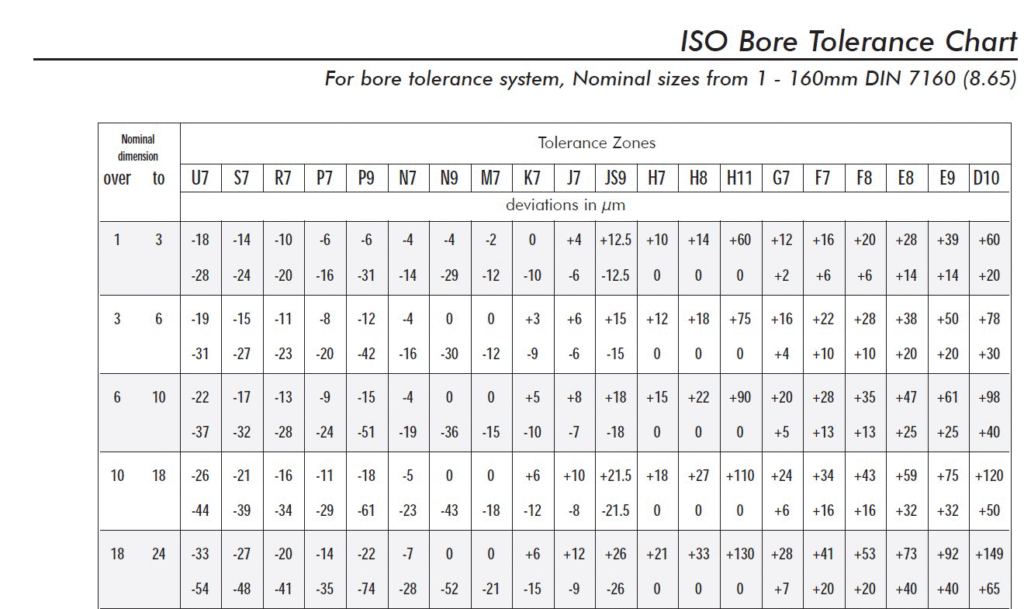

Tolerance, on the other hand, will depend on how accurate the bore size is. In simple words, when you say you need a 12 mm bore in H7 tolerance, you mean that the bore size can be between 12 mm and 12.018 mm. Thus, the male component or let us say the shaft size will be from 11.983mm to 11.994 mm so the fitting is quite snug and can be easily assembled or disassembled. E.g., in H7 tolerance, with a diameter size of 12 mm, you may expect a tolerance range of 18 microns or 0.018 mm. If you dig a little deeper, you will find that if the hole size is 12.00mm, then the component or shaft will be 11.983 mm. Alternatively, it can be 12.018 mm for the bore Vs. 11.994 mm shaft at max. So, it gives min difference between the two components as 0.006 mm or 0.035 at max.

You may refer to the ISO Bore Tolerance Chart here.

Surface Finish refers to the surface crests and troughs of the inner surface of the bore made. Essentially, it depends on the tools being used and the parameters on which the machine is being run. In general, if all other things are in order, increasing the spindle speed or RPM of the machine and decreasing the feed of the tool improves the surface finish. The surface finish becomes important in the case of finish products where the component is already hardened and there will not be any surface treatment like black oxide, sandblast, chrome, or any other type of coating.

Where not to be used?

Ever heard of the term interpolation? In a CNC Machining Center (known as a Vertical Machining Center is some parts of the world), users will program the tool to move three axes, namely, X, Y, and Z simultaneously to make a hole. This makes it necessary to calculate different data points between given positions of the coordinate axis. For more detailed information, you may refer to this article by Peter Smid. This becomes important and perhaps economical to not use a boring head for cases where there will be very little requirement of boring operations in a workshop. More importantly, it is useful where tolerances are not very tight and you can work with ovality or chatter to a certain extent.

Type of Boring Tools/ Boring Bars

There are three common types of boring bars or boring tools used with a Micro Boring Head. The High-Speed Steel, Tool Steel, and Solid Carbide. The High-Speed Steel or HSS as it is commonly known is a globally renowned and perhaps loved one more so as it is easy to work with and more easily available. These tools will give a good process finish to the extent where the L/D ratio is 2 or 3. Above this level, you may want to switch to boring bars made from tool steel.

Set of 20 mm Tool Steel Boring Tools with Dia 75 mm Boring Head Boro-tech

8pc German Type HSS Boring bar set 8mm shank

More recently companies such as Sandvick have introduced anti-vibration tools for making deeper bores while maintaining tighter tolerances and surface finish both for Turning as well as Machining Centers.

We shall cover the structure and parts of a boring head in our next write up.

Till then keep machining.

Do like and share and spread the word.